BUILD Workshop 2024

Overview

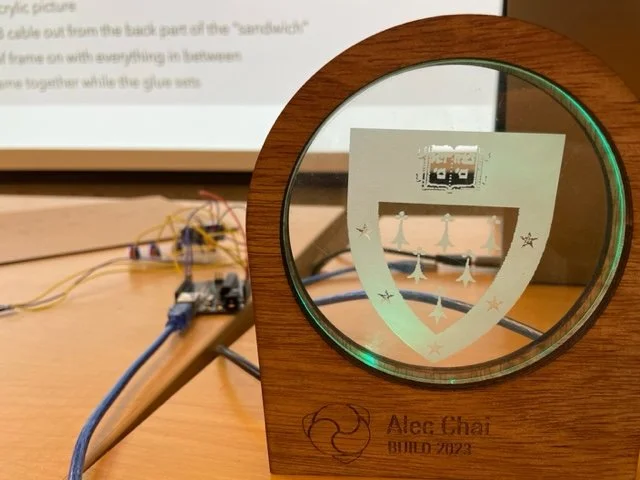

I was asked to create and lead a 1.5-hour workshop for 20 incoming Yale undergraduates interested in engineering and computer science. I created these elegant, personalized, and rapidly producible souvenirs to introduce basic concepts of manufacturing and Arduino programming.

Timeline: 1 week

Design

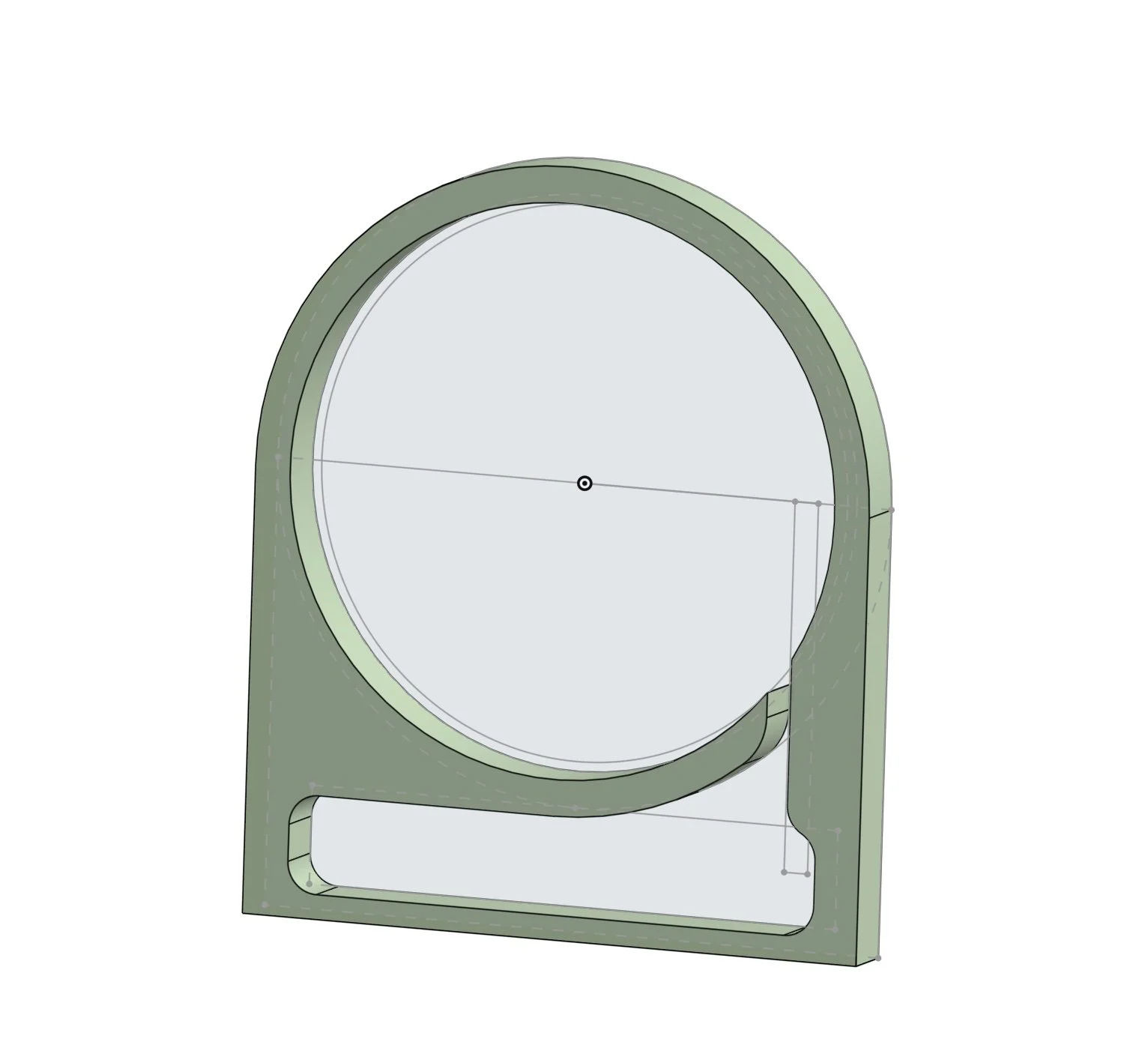

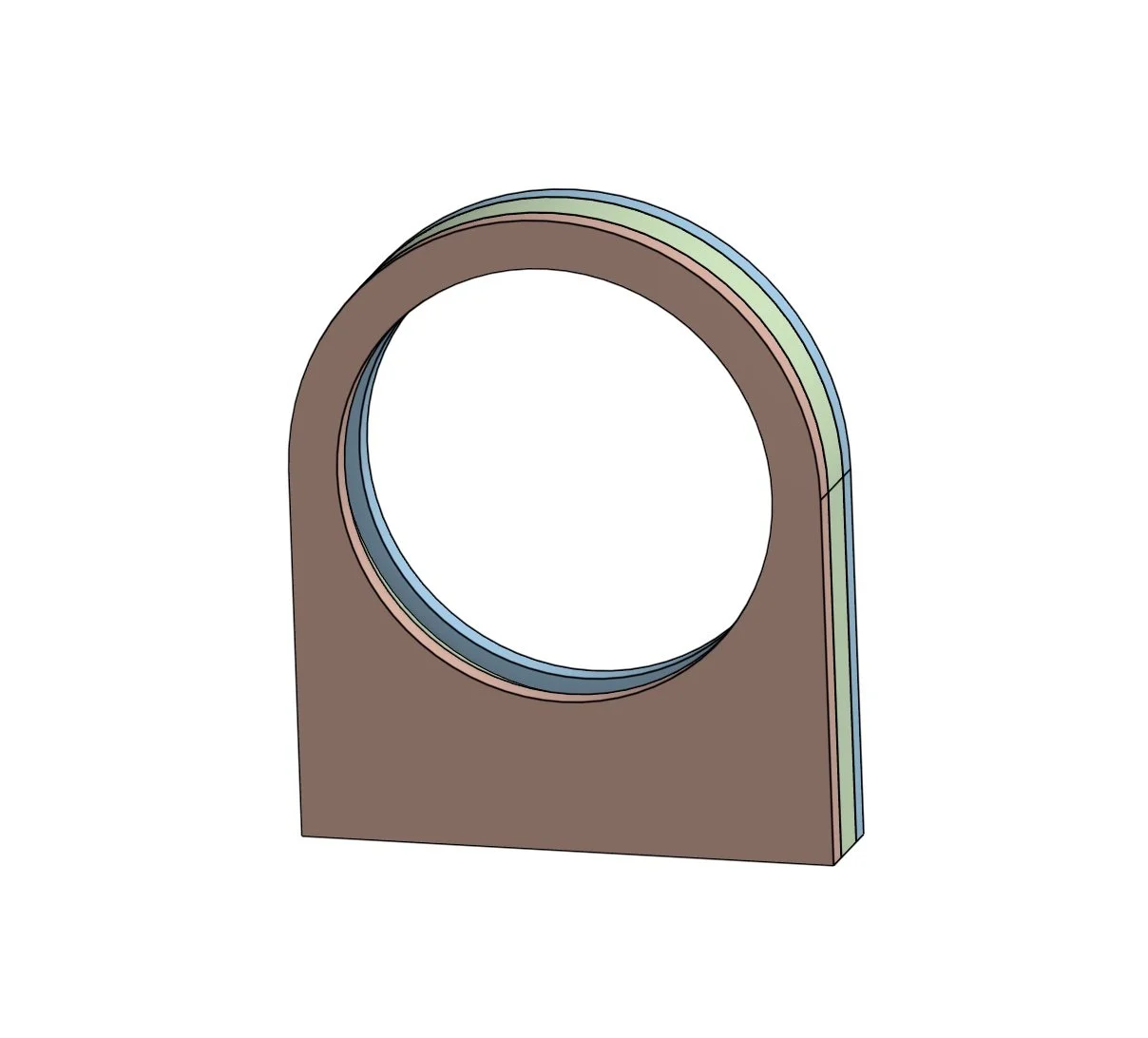

To create a lasting impression, I designed unique edge-lit picture frames for each student. The initial design included a 3D-printed frame with a 0.5” acrylic insert, surrounded by individually addressable LEDs. The frame was to house an Arduino Nano in a compartment at the bottom, with an exit port for a miniUSB cable. However, due to equipment malfunctions—nearly all of our FDM printers jammed or broke—I had to pivot quickly to a new design.

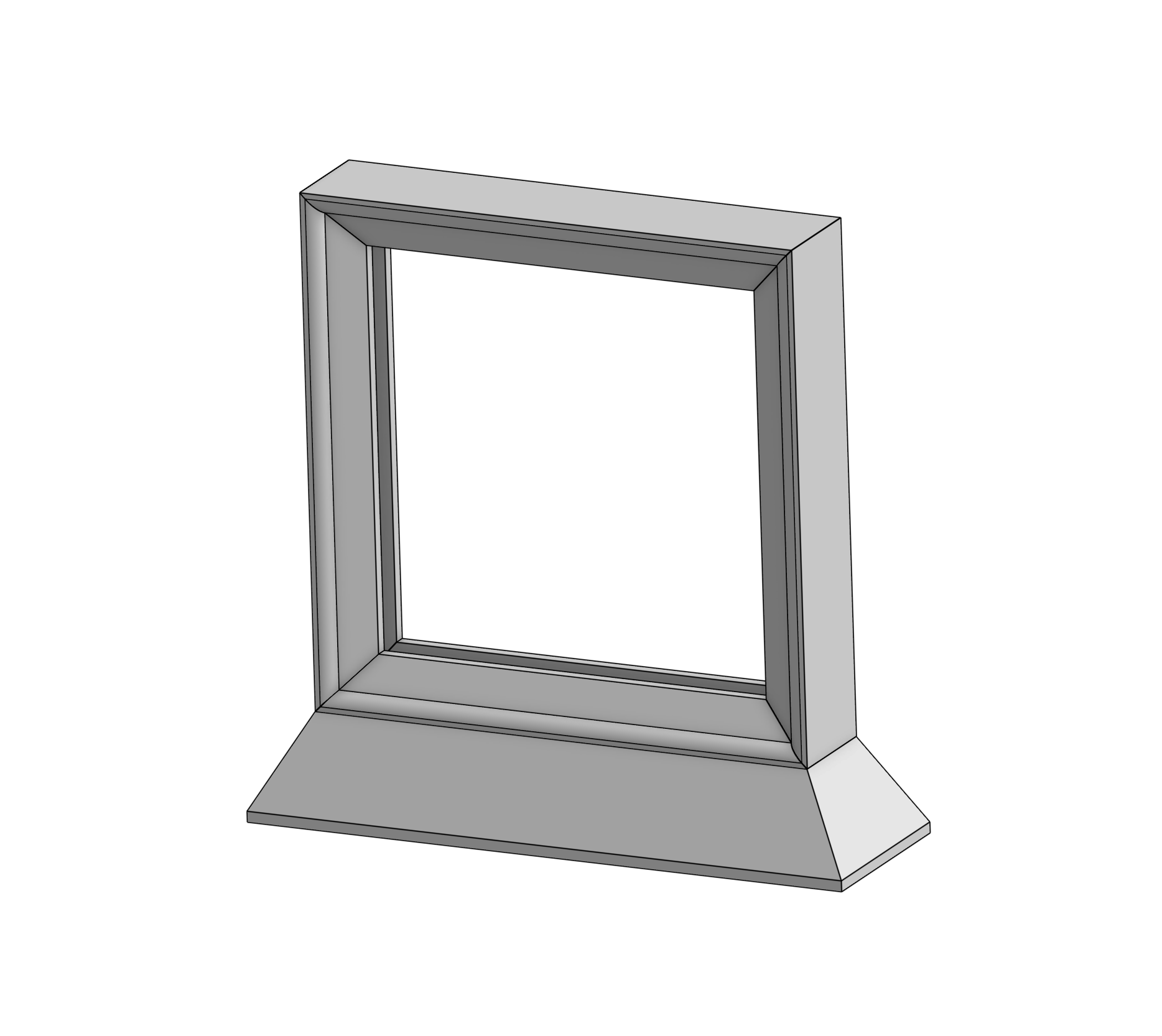

I redesigned the frames using wood, opting for a layered approach that could be laser-cut in minutes. The wooden frame consisted of three layers: the front layer, engraved with the student’s name; the middle layer, which housed the electronics; and the back layer to complete the structure.

Acrylic Photos

To make the frames stand out, I engraved each student's Residential College shield on the acrylic. Clear acrylic turns white when engraved, so I preprocessed the images by flipping them to negative, converting them to grayscale, and then using 1-bit dithering algorithms to maintain contrast. This allowed for a clean and striking representation of the shields when lit from the edges.

Workshop

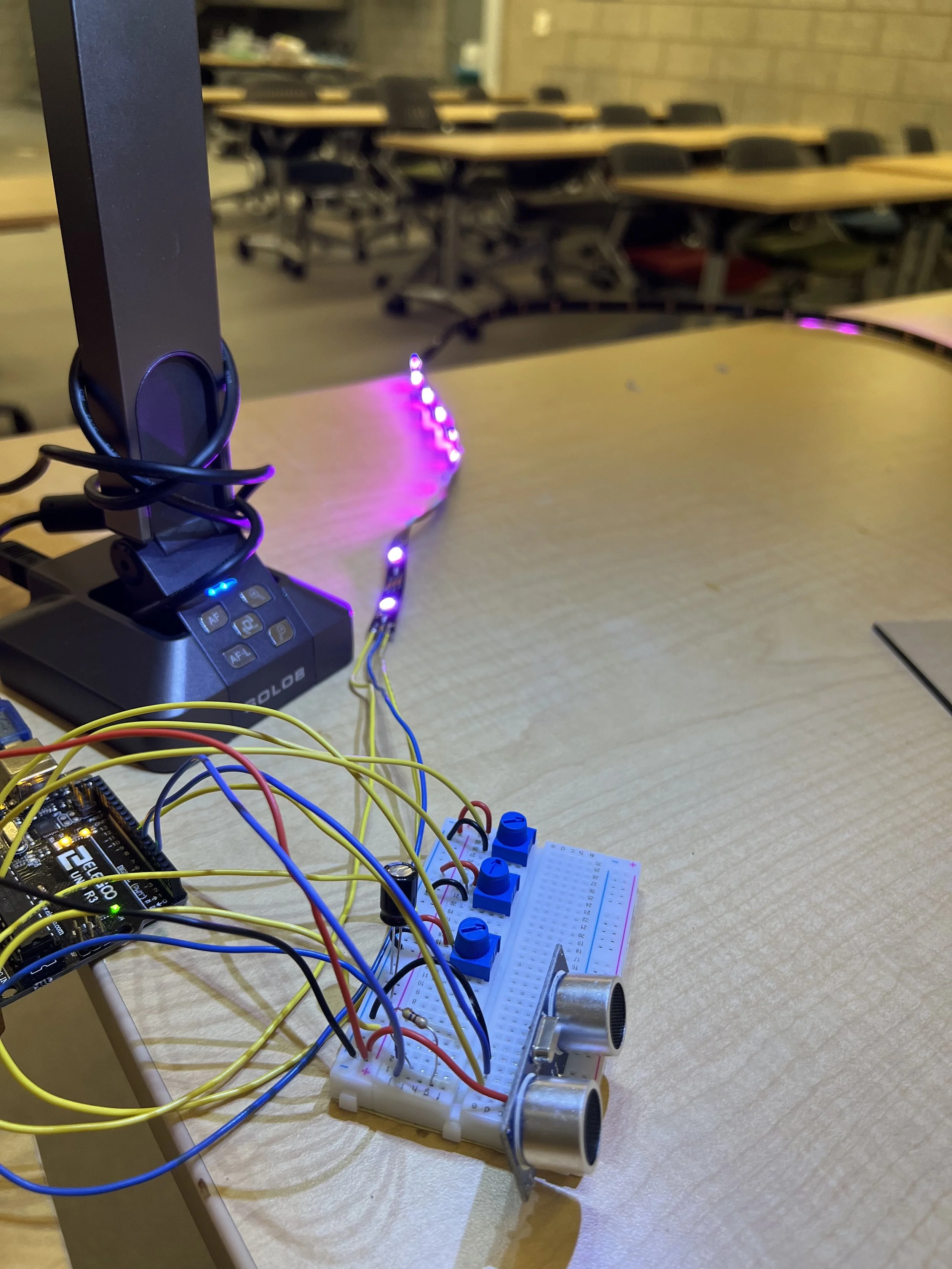

During the workshop, I gave a presentation covering the following topics:

Introduction to Arduino

Hardware demonstrations using potentiometers, ultrasonic sensors, and LEDs

Introductory coding for controlling LED strips

Students had the option to copy/paste provided code or create their own custom LED behavior, with the codebase available on my GitHub. After programming their LEDs, the students assembled their frames using wood glue, completing their personalized souvenirs by the end of the session.

Conclusion

The workshop was a success, providing students with a hands-on introduction to both manufacturing and Arduino programming in a short timeframe. Despite the challenges of equipment failure, the pivot to a laser-cut design allowed for rapid production while maintaining the personalized, high-quality feel of the souvenirs. The students left with not only a deeper understanding of the technology but also a tangible, functional keepsake that reflected their budding skills. This experience highlighted the importance of adaptability in design and teaching, as well as the value of creating engaging and meaningful products in a short period of time.